Here are some easy steps to get your wall ties right:

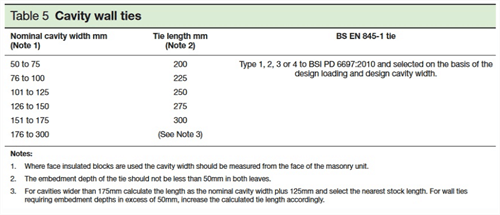

- The length of wall tie needed is specified in table 5 of Approved Document A of the Building Regulations, reproduced below.

- You need two and a half wall ties per square metre of masonry. The maximum horizontal spacing is 900mm and the maximum vertical spacing is 450mm. That’s why cavity wall insulation boards usually have a maximum dimension on the short edge of 450mm.

- Set each wall tie a minimum of 50mm into both masonry leaves.

- Lay the wall ties to a slight ‘outward’ fall to prevent water passing to the inner leaf.

- Only use insulation retaining clips that are compatible with your tie.

- Change the wall tie pattern around openings such as windows, doors, roof verges and movement joints. Here the vertical spacing is reduced to a maximum 300mm and should be within 225mm of the opening. So realistically, that’s a wall tie every course of blocks within 225mm of the opening, which means you need to carefully cut (and clip) the insulation.

- Cavity wall ties should be stainless steel.

Follow these simple rules and you’ll meet the Building Regulation requirements every time.