Provision of information

- A site-specific design must be provided before the relevant works start on site. A checklist of points which must be considered as a minimum for warranty purposes is included at the end of this article.

- Third party product conformity certificate for the single skin metal roof build up must be provided (see the general requirements section for further details).

- Evidence the installer being used has been approved by the product/system manufacturer.

What is a fully supported single skin metal roof?

The specification of fully supported single skin metal roofs has become increasingly popular on projects, and their general build-up consists of a structural deck (usually metal or timber), fully supported vapour barrier, insulation such as mineral board or polyisocyanurate (PIR), separation membrane and an external metal sheet. The exact build-up of the roof structure may differ, but the general principles are that the external metal sheet is fully supported on a suitable material.

General requirements

Best practice

All designs should be in line with the latest edition of Federation of Traditional Metal Roofing Contractors (FTMRC) UK Guide to Good Practice in Fully Supported Metal Roofing and Cladding (ftmrc.co.uk).

Third party product conformity certification

For fully supported zinc warm roof systems, the entire build-up must have a third party product conformity certificate from a United Kingdom Accreditation Service (UKAS) accredited body. The certificate should clearly detail all of the components used and the build-up the certificate relates to. The certificate should carefully be reviewed by all interested parties to ensure all of the conditions within the certificate are satisfied.

Please note, we will not be able to accept any materials or components being substituted from those detailed in the certificate.

Cold pitched roof build-ups do not require a third party product conformity certificate, however the building designer should carefully consider the following points as discussed in this guidance: incompatible materials, separation layers, underside coating to the external metal sheet and ventilation to the cold roof space.

Fully supported single skin metal roofs are not permitted in a cold ‘flat roof’ build up.

UKCA Marking

All products and components should have UK Conformity Assessed (UKCA) marking in accordance with UK Construction Product Regulation.

Site-specific design

Throughout this article, the term ‘site-specific design’ will be used. Where a fully supported single skin metal roof is specified, we require the designer to consult with the manufacturer to go through some of the key risk areas discussed in this document.

The site-specific design should be provided as early as possible so it can be reviewed by the warranty surveyor before any works to the roof covering is started. A checklist is provided at the end of this article highlighting the areas the site specific design must cover as a minimum for our warranty purposes.

Underside corrosion

All metal roofs are prone to underside corrosion (to varying degrees) when moisture becomes trapped between the metal and the substrate (structural deck) and oxygen and carbon dioxide are not able to form a protective layer to the underside (patina). Underside corrosion can also occur where incompatible materials are specified. The following sections will provide guidance on how to prevent underside corrosion.

The internal humidity class and deck type should be considered carefully to avoid issues of interstitial condensation and potential underside corrosion.

Internal humidity class and deck type

The influence of the type of building occupation cannot be underestimated when considering condensation risks. Occupants and their many activities create a moisture load for the structural elements to deal with, and unsurprisingly as occupants increase in number, the moisture load on the building increases.

As moisture can accelerate the onset of corrosion to unprotected metal sheets, this creates an increasing importance on the arrangement of vapour control layers within the built element in controlling this risk. Many fully supported metal roofing systems use a product specific air and vapour control layer (AVCL) to reduce this risk so particular attention should be paid to the correct and system specific requirements in this area.

For warranty purposes, ‘humidity class 3’ will be adopted as the internal humidity class for a residential property. (I.e. high or unknown occupancy) See table 1.

Equally, the structural deck material should be considered with great care. The use of fully supported metal roofing systems on large span commercial buildings was routinely coupled with metal deck materials, which have an inherent resistance to moisture and vapour.

The adoption of fully supported metal roof coverings into the residential sector has resulted in wood based panels (plywood or oriented strand board) being used instead of metal as a structural deck. This switch to the use of timber decks plus the increased levels of humidity can result in moisture reaching the underside of the metal sheet.

For the purpose of obtaining warranty, as timber decks offer less resistance to moisture, their use should be restricted and only considered when a condensation risk analysis has been carried out.

| Humidity class | Building type |

| 1 | Storage areas |

| 2 | Offices, shops, dwellings with low occupancy |

| 3 | Dwellings with high or unknown occupancy |

| 4 | Sports halls, kitchens, canteens, school classrooms, hospitals, buildings headed with unflued gas heaters |

| 5 | Special buildings (laundry, brewery, swimming pools) |

Table 1: Humidity class and building type, derived from BS5250:2021

Compatibility of materials and separation layers

Underside corrosion can also be caused by incompatible materials being specified together. Table 2 shows which metals should not be used together. It’s important to consider both direct contact and surface run-off from incompatible materials; for example with the use of rain water goods. If the use of incompatible materials cannot be avoided, they should be separated from each other by either non-conducting, non-metallic isolators (seals and grommets in fixing systems) or coated with compatible or inert materials.

Timber treated with certain types of preservative, particularly of copper‑chrome‑arsenic formulation, can cause corrosion of zinc, carbon steel and aluminium in contact with the timber. As such, external metal sheets supported on any timber deck such as plywood must have a factory applied coating specified and be separated from the timber deck by a compatible separation membrane as specified by the system manufacturer.

In addition to the incompatibility issues highlighted above, external metal sheets can also be susceptible to incompatibility issues with other common materials. Zinc for example may be incompatible with materials such as, bituminous membranes, mortar and building paper. In all situations, the metal sheet manufacturer should be consulted with regards to incompatible issues and this should be highlighted in the site specific design.

| Al | Pb | Cu | Zn | S.S | G.S | |

| Aluminium (Al) | ✓ | ✓ | X | ✓ | ✓ | ✓ |

| Lead (Pb) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Copper (cu) | X | ✓ | ✓ | X | ✓ | X |

| Titanium zinc (Zn) | ✓ | ✓ | X | ✓ | ✓ | ✓ |

| Stainless steel (S.S) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Galvanised steel (G.S) | ✓ | ✓ | X | ✓ | ✓ | ✓ |

(1) Steel hollow rivets are not compatible when used externally

(2) Galvanic copper plating of galvanised components can increase corrosion development; They do not provide corrosion protection

Ensuring correct membranes are used

Underside corrosion can also manifest itself where either incorrect membranes have been specified, or the correct membranes have been specified, but they’ve been substituted for an inferior product post design approval.

All of the membranes specified in the site specific design must be in line with what is specified in the third party product conformity approval certificate. For cold pitched roofs without a third party product conformity approval certificate, membrane specification and compatibility should be carefully considered by the designer and consultation with the metal sheet manufacturer is recommended.

The membranes should not be substituted and they should be checked to match the approved specification by the site manager and installer prior to the roof covering being laid.

Air and Vapour control layers (AVCL) should have a minimum vapour resistance between 5000-7000 MN.s.g. This is best achieved with the use of self-adhesive aluminium foil backed modified bitumen membranes (manufacturer’s guidance should be sought before installing if the foil is torn). An AVCL should always be on the warm side of the insulation. Care should be taken around correct detailing for penetrations.

Any breather membrane specified below the external metal sheet must be suitable and compatible for use in this area.

Roof build ups, ventilation and condensation

A lack of sufficient ventilation in some of the build ups can lead to issues such as interstitial condensation and underside corrosion. We will now consider some of the roof build ups and their correct specification.

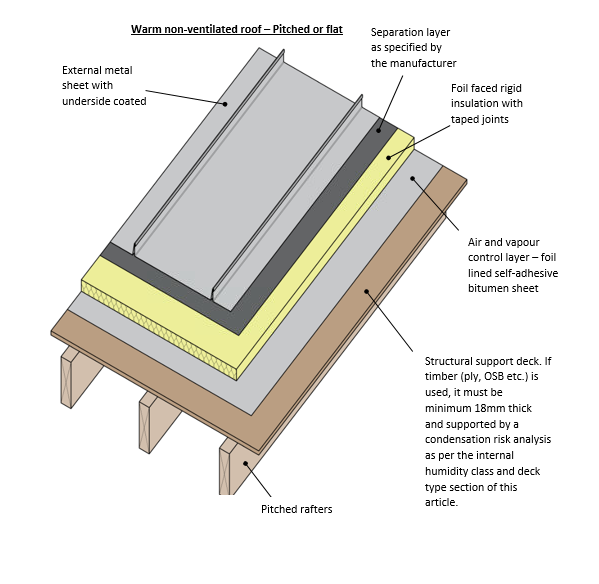

Warm non ventilated roof – pitched or flat

Constructed without a ventilation provision, the warm deck roof relies on the moisture resistant properties of the fully sealed AVCL that sits beneath the insulation. It is critical that this layer is as specified in the system manufacturers’ guidance, with its integrity remaining undamaged during construction. Any fixings from layers above must be fully considered in design with provisions for sealing penetrations. Untreated, they may give risk to moisture transfer and increase the risk associated with interstitial condensation and a premature failure of both the external metal sheet and supporting material. Mechanical fasteners should be avoided above conditioned spaces with high humidity like swimming pools and gymnasiums. The approach may be employed on both flat and pitched roofs.

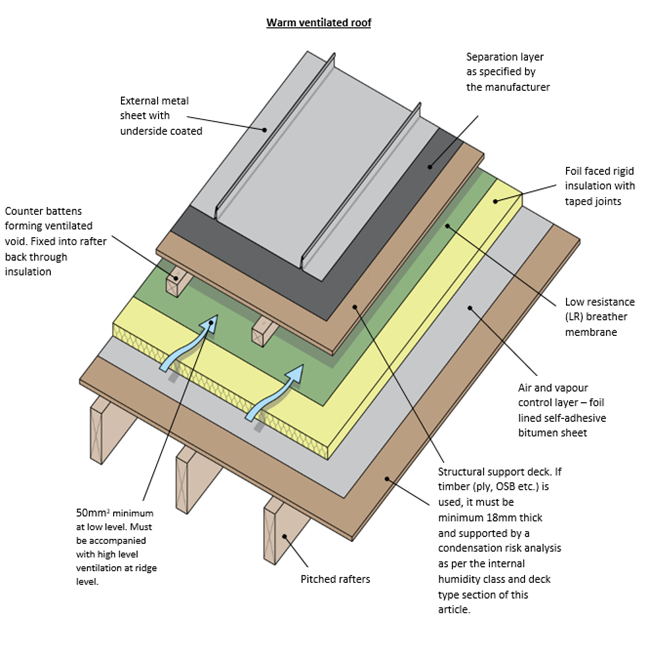

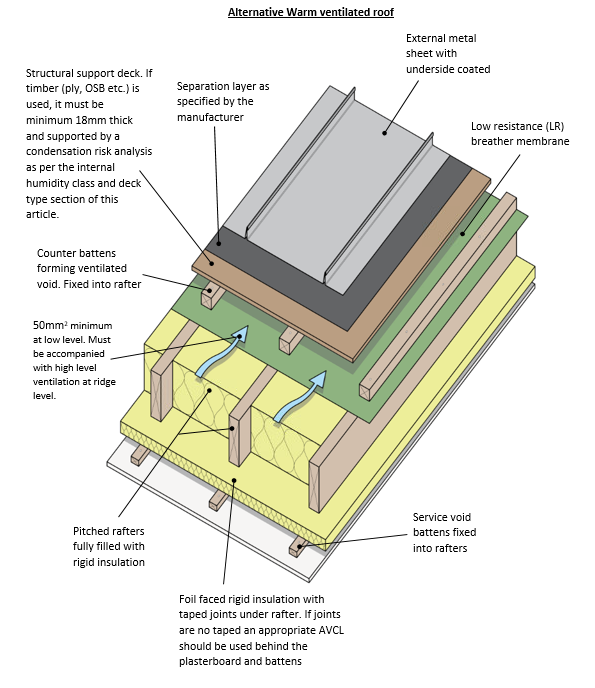

Ventilated warm roof

The ventilated warm roof arrangement incorporates a well-sealed AVCL and a well ventilated void between the supporting boarding to the underside of the external metal sheet and the overlying low resistance breather membrane layer, this ventilated roof void allows for any moisture escaping through the fabric to be expelled by a cross-flow of air. The span of the roof should be considered when using this approach as larger spans will require an increase to the void depth and eaves ventilation provisions.

Cold ventilated ‘pitched’ roof

Cold ventilated ‘pitched’ roof

The cold pitched roof arrangement requires ventilation at low level and at high level as per guidance in chapter 11 of our Technical Manual as the timber deck prevents any warm air escaping.

Other considerations

External environments

External metal sheets can degrade at a faster rate in certain chemically corrosive environments. These can include, coastal locations or sites in close proximity to manufacturing facilities such as chemical works, cement works, copper foundries or coal mines; this can have an impact on the durability of the product.

Where external metal sheets are used in chemically corrosive environments as specified above, a third party product conformity certificate must be available for the external metal sheet (for both warm and cold pitched roofs). The third party product conformity certificate must clearly state the product has been assessed for use in a chemically corrosive environment and it has at least a minimum life expectancy of 15 years. The third party product conformity certificate should be forwarded to us for consideration as early in the build process as possible.

Where local conditions are chemically corrosive as highlighted above, periodic cleaning may be necessary, advice should be sought from the manufacturer

Fire classification

The entire system (not just the external metal sheet) should be assessed to meet the requirements of the building regulations, Approved Document B in England and Wales. In particular, the entire system must meet B4 of Approved Document B. For further guidance, advice should be sought from your building control body.

Approved installer

Due to the complex nature of external metal sheet roofing, we require the installer to be approved by the manufacturer. Where the manufacturer doesn’t retain a list of approved installers, evidence should be provided showing the installer is competent and trained with external metal sheet roofing.

Deck exposure during construction

Any membrane applied during construction that is left open should be capable of resisting moisture penetration. In the event that a LR membrane is used, the deck should be assessed in relation to its moisture content before any further layers of building fabric are applied. Moisture content of timber boarding should not exceed 20% at point of roof covering being applied.

Ply bonded on insulation

Ply or timber topped insulation should not be a site-formed configuration. Ply or timber topped insulation boards should be subject to the factory environment controls and quality assurance procedures to ensure they are fit for purpose. Their overall performance inclusive of structural capabilities, compatibility and durability should be subject to assessment utilising suitable a Third party product conformity certificate as a minimum.

Expansion

If timber such as plywood is used for the structural support deck, movement gaps should be considered for square edged boards at rigid upstands and between boards. A minimum gap of 3mm needs to be maintained between boards and 10mm with rigid abutments.

Checklist for manufacturer’s site-specific design

As a minimum, the site specific design should include all of the following points:

- The document must reference the third party product conformity certificate (for the complete system, not only individual components) to confirm this has been reviewed in line with our warranty requirements (not applicable to cold pitched roofs).

- The location of the development must be reviewed; if the location is a chemically corrosive environment as highlighted in this article, reference should be made to the third party product conformity certificate confirming it is suitable for use with a minimum life expectancy of 15 years.

- The manufacturer should be consulted with regards to the site-specific fixing specification for the external metal sheets.

- Roof build up needs to be detailed and this must match what’s in the third party product conformity certificate (for the complete system, not only individual components) and the build ups highlighted in this article.

- A list of components to be used needs to be provided and any incompatible components should be clearly highlighted. Details for methods of separation between incompatible materials (location, type and method of fixing) must be specified. If there no separation layer between the external metal sheet and the timber deck, this needs to be justified.

- Details of protective coating applied to the underside of the external metal sheeting needs to be highlighted (type and thickness of coating). Protective coatings must be factory applied.

- Air and vapour control layers (AVCL’s) should have a minimum vapour resistance of 5000-7000 MN.s.g. This must be detailed in the site-specific design.

- A condensation risk analysis must be provided with reference to the humidity class used.

Warranty stance

Fully supported single skin metal roofs have a lot of associated risks as highlighted in this article, however these risks can be mitigated with attention to detail in the design and ensuring what is installed is as per the third party product conformity certificate and manufacturer’s details.

Every care was taken to ensure information in this article was correct at the time of writing (DATE). Guidance provided does not replace the reader’s professional judgement and any construction project should comply with the relevant building regulations or applicable technical standards. For the most up to date LABC Warranty technical guidance please refer to your risk management surveyor and the latest version of the LABC Warranty Technical Manual