Identifying green, air dried (seasoned) or certified kiln dried oak

Where timber has been dried and has a moisture content less than 12%, it will usually be marked with a stamp saying “DRY” or “KD” (for kiln dried), however, if timber has been cut or machined, it is likely these stamps are not visible, in such circumstances, proof of purchase confirming that timber is kiln dried should be provided.

The purpose of this article

This article identifies in the following tables, various ‘environments’ where ‘oak’ could be used on project covered by our warranty. The tables identify the ‘oak type’ and the applicable insurance policy. A simple ‘yes’ or ‘no’ indicates whether oak can be accepted for our warranty purposes. Additional guidance notes (where applicable) help clarify our insurance stance.

Whilst the Technical Manual is clear on the use of green oak and any new orders for project are received with the understanding oak will not be acceptable in most circumstances, there may be a situation where a change in specification occurs post offer of warranty or it may not have been disclosed at the time of application that oak is intended. For these situations, surveyors and developers must be aware of these ‘environments’ where oak is not acceptable.

List of environments

- “Through wall” oak framed construction forming part of the waterproof envelope

- Internal frames not forming part of the waterproof envelope

- “Open” canopies

- “Enclosed” porches

- Structural oak embedded into the ground

- External windows and doors

- Second fix joinery (internal)

- Attached garages constructed of oak

- Any detached garages

- External cladding

- Mock Tudor cladding (decorative cladding)

- External embedded oak lintels

- External timber balconies (including oak) more than 2.4m above external ground level

- Masonry cladding fixed back to outer leaf of cavity masonry wall and supported on oak Tudor cladding

Abbreviations:

- NH: New Homes policy

- SH: Social Housing policy

- PRS: Private Rental Scheme

- Self-build: Self-build

- CH: Completed Housing

- CB: Commercial buildings

Environment 1

Through-wall* oak framed construction

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | No | No | No | No | No |

Notes:

*Through-wall timber construction, of ANY species, is NOT acceptable for warranty purposes.

Environment 2

Internal frames not forming part of the waterproof envelope

Including floor beams, floor joists, trusses and purlins, where any movement in the oak WILL NOT affect the waterproof envelope.**

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | Yes | Yes | Yes | Yes | Yes |

Notes:

^Max 12% moisture content

**Providing the structural engineer proves that any shrinkage/twisting in the oak will be catered for and be isolated from the waterproof envelope.

Environment 3

Open canopies

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | Yes 1,2 | Yes 1,2 | Yes 1,2 | Yes 1,2 | Yes 1,2 |

| Kiln dried | Yes 1,2 | Yes 1,2 | Yes 1,2 | Yes 1,2 | Yes 1,2 |

Notes:

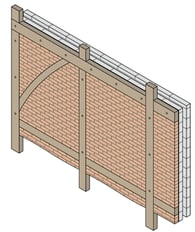

1. The canopy must not exceed 3m2 and should be structurally independent from the dwelling with no timber element built into the external walls, see top image.

2. The canopy roof must not link with the roof over the main property as shown in bottom image.

Environment 4

Enclosed porches

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | No | No | No | No | No |

Notes:

This applies to porches being built prior to completion of the house (i.e. part of the housing unit)

Environment 5

Structural oak embedded into the ground

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | No | No | No | No | No |

Environment 6

External windows and doors

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | Yes 1 | Yes 1 | Yes 1 | Yes 1 | Yes 1 |

Notes:

1. The requirements in Section 8 of the Technical Manual must be met (including that of weathertightness)

Environment 7

Second fix joinery (internal)

Including floor boarding, skirting boards, internal doors, stairs

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | Yes | Yes | Yes | Yes | Yes |

Notes:

Reclaimed oak will be acceptable where it is proven to have a moisture content below 20%

Environment 8

Attached garages constructed of oak

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | No | No | No | No | No |

Environment 9

Any detached garages

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval |

| Air dried | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval |

| Kiln dried | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval | No - exclusion subject to approval |

Notes:

Oak is not acceptable for use outside the guidance provided in this document.

An exclusion may be applied to the policy, where oak is incorporated into a detached garage, subject to our agreement. Such an exclusion may only be applicable to the detached garage and cannot be applied to the home.

If an exclusion is approved:

A. The developer will be made aware from the outset of our concerns over the use of oak and the potential impact on the sales and future sales prices that this exclusion of the detached garage from our warranty cover this may have.

B. We will require written confirmation of the policyholder’s acceptance of the exclusion of the detached garage from the policy, prior to sign off.

C. The developer will need to understand that, if a purchaser is unwilling to accept the exclusion being applied to the policy for the detached garage which contains oak, we will be unable to offer warranty cover for the property irrespective of the stage of build.

D. The warranty surveyor will not sign off a property containing an oak detached garage until we have received the developer’s/policyholder’s acceptance and we have confirmed in writing that the policy has been endorsed to exclude the oak detached garage.

Environment 10

External cladding

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | Yes 1 | Yes 1 | Yes 1 | Yes 1 | Yes 1 |

| Kiln dried | Yes 1 | Yes 1 | Yes 1 | Yes 1 | Yes 1 |

Notes:

1 For cladding purposes:

- The oak must be installed with a moisture content around 16%

- The developer must take into consideration movement and potential shrinkage; ensure fixings are compatible with oak: i.e. stainless steel. Substrates and drained and vented cavities must comply with the Technical Manual

- A second line of defence must be provided by the provision of a suitable breather membrane to protect the inner structural frame (as well as the drained and vented cavity)

- Further guidance can be found in the TRADA 3rd edition ‘External Timber Cladding’

Where cladding is installed, this must be subject to meeting the requirements.

Environment 11

Mock tudor cladding (decorative cladding)

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | Yes 2 | Yes 2 | Yes 2 | Yes 2 | Yes 2 |

| Kiln dried | Yes 1 | Yes 1 | Yes 1 | Yes 1 | Yes 1 |

Notes:

1 The developer should:

- Fix cladding onto a continuous render substrate (not render infill between timbers)

- Fix timber using stainless steel screws that are at least 3 times the depth of the timber and appropriate for the substrate

- Ensure substrates comply with Section 6 of the warranty Technical Manual

NB. A further Technical Update is available on mock Tudor cladding

2 Kiln dried is the preferred option in order to reduce the potential for curling.

Environment 12

External embedded oak lintels

Structural or non-structural, with or without relieving lintels

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | No | No | No | No | No |

Notes:

Concrete or steel lintels are appropriate for use in masonry walls. Support for masonry should not be provided by timber lintels, regardless of the timber species.

Decorative timber cladding may be acceptable, to provide a mock timber lintel/beam effect. The mock timber must be planted onto the face of the wall and not embedded into the wall. In this situation please refer to the guidance above in Environment 11.

Environment 13

External timber balconies

including oak - more than 2.4m above the external ground level

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | No | No | No | No | No |

Notes:

Balcony construction, of ANY timber species, is NOT acceptable for warranty purposes where the balcony is more than 2.4m above the external ground level.

Environment 14

Masonry cladding

Fixed back to outer leaf of cavity masonry wall and supported on oak Tudor cladding

| NH & SH | PRS | Self-build | CH | CB | |

|---|---|---|---|---|---|

| Green | No | No | No | No | No |

| Air dried | No | No | No | No | No |

| Kiln dried | No | No | No | No | No |

Notes:

This type of build-up should not be accepted in any circumstance as the oak is supporting the brickwork panel which is connected back to the outer leaf of masonry. Any movement in the oak and brickwork will be transferred back to the outer leaf.