Key risks

Gust wind speeds, in combination with rain, can create design issues for buildings sited in shoreline locations, particularly cladding and roof coverings and their associated fixtures and fittings. The slightly less obvious risks of durability, workmanship and maintenance, equally impact on the longevity of a building. For example, the effects of corrosion from wind-blown salt spray and higher UV exposure will reduce the expected durability of a finish or a component in a coastal location to less than 10 years, in some cases as short as 5 years.

Failures directly due to poor workmanship rather than the failure of the actual material are common. For example:

- Poor installation of roof tiles or slates due to lack of correct fixings required for the location

- Inadequate provision of correct damp proofing in walls around openings e.g. poorly fitted cavity trays

- Incorrectly positioned flashings and DPCs to balconies especially around external door opening junctions

Whilst it’s the designer’s responsibility to ensure that exposed components must be fit for purpose, some materials and particularly finishes will, due to the environment, require an on-going maintenance to keep a satisfactory finish. Maintenance plans will need to be drawn up by the designer to ensure premature failure of coatings or components is avoided. The building owner must then take responsibility to ensure that regular maintenance of exposed components and finishes is carried out. For example:

- Debris build up (e.g. wind-blown sand) must be managed, particularly to balconies. If not managed, blocked outlets can cause overflowing leading to water ingress internally as well as unsightly stains to external masonry and timber claddings

- Bi-fold and patio-type doors are vulnerable for the seals, mechanisms and drainage holes being affected by wind-blown sand if not regularly maintained

Masonry wall constructions

In severe and very severe categories of exposure, external walls should incorporate additional protective features to avoid excessive wetting of the masonry. Features such as deep overhanging eaves and verges, projecting sills and checked window reveals should be incorporated into the design

The following should be avoided in very severe exposures:

- Flush sills and inadequate or non-existent overhangs at verges

- Large expanses of glazing or impermeable cladding with no effective means to shed run-off water clear of the masonry below

- Rendering and masonry junctions with no effective seal to prevent water penetrating the rear of the render

Rendering

The ‘background’ or substrate which supports the render must be suitable for bonding the render to and be sound and dry in condition. Hand mixed renders should not be used. Only pre-blended bagged render systems will be accepted that have a third party accreditation such as a BBA or ETA certification and backed up with a manufacturer’s specification. In a very severe location, a detailed specification from the render manufacturer will be required to justify it is suitable for the proposed conditions and the overall thickness.

Render angle beads should be appropriate for the environment. Non-corrosive render beading e.g. PVC or marine grade stainless steel should be installed.

External cladding systems including rainscreens

The materials used within the construction should be capable of withstanding weathering and atmospheric pollution and potential chemical attack for the intended design life. The system must have a current third party product approval, confirming the specification is suitable for a coastal environment.

Window and doors

The choice of windows and doors must be supported by manufacturer’s certification to confirm they meet the design weather conditions and have proof of testing to the following weather performance standards:

- BS 6375-1 Weather tightness

- Air permeability - BS EN 12207 – Classification & BS EN 1026 - Test method

- Water resistance - BS EN 12208–Classification & BS EN 1027 - Test method

- Wind resistance - BS EN 12210–- Classification & BS EN 12211 – Test method

Window and door furniture and fittings must be resistant to the effects of the saline environment.

Balconies

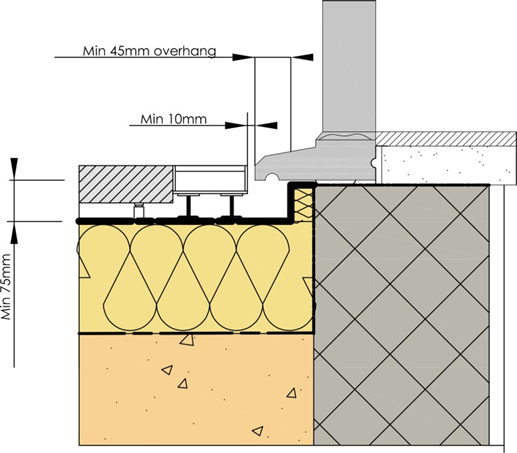

The balcony roof waterproof covering must be designed to fall away from any external door openings into the building. An adequate step or raised threshold must be provided to avoid the risk of wind driven rain penetrating the construction. A minimum of 75mm difference between the highest point of the balcony roof waterproof surface and the underside of the door sill may be provided as the detail below, otherwise in all other situations, a 150mm should be provided.

Drainage outlets must be easily accessible and maintainable even if decking / balcony floor finishes are applied. Balcony steelwork must be adequately protected against the potential for corrosion.

Protective coatings and finishes to metals

All metals must have a suitable protective coating to minimise or prevent corrosion during its life.

- Steel used on sites within 500m from a coastal shoreline should be galvanised to a rate of 710 g/m2

- Decorative finishes must be compatible with BS EN 12944 and the manufacturer’s recommendations

- Steel lintels used in both leaves of an external wall should be austenitic stainless steel and in addition, protected by a separate damp proof system / cavity tray

- The use of intumescent paint to achieve fire protection should be compatible with any corrosion protective coating applied. The manufacturer’s guidance should be followed.

Roofs

For clay, concrete and slate roofing, a full roof fixing specification from the slate or tile manufacture must be provided and take into account the exposure, environment and orientation of the site.

For metal cladding, the designer must establish the environment’s corrosivity when specifying metal cladding as well as the potential for wind uplift and movement in a cladding system during severe wind conditions, particularly over party wall positions.

Warranty position

This article has provided some guidance on how the functional requirements of our technical manual can be satisfied for developments in coastal locations. For further information please refer to Appendix B of the LABC Warranty Technical Manual.