What happens to mortar in cold weather?

If frost attacks mortar it loses its key and the strength of the wall can be compromised. Rain penetration can also wash fines onto brickwork or into a cavity making the wall look unsightly. Both can also worsen sound insulation if mortar is forced into a cavity. Likewise, timber frame sheathing can swell when wet and reduce the cavity’s acoustic performance.

How cold can you work with mortar?

To meet the functional requirements of Appendix C of our Technical Manual, minimum working temperatures should never fall below 2°C when working with masonry. It is imperative that regular temperature readings are taking when working during cold weather periods.

Thermometers should be placed away from direct sunlight, preferably in a shaded area. It’s important to consider wind chill and weather exposure when assessing the temperature. Make necessary allowances for those sites which are deemed to have higher levels of exposure.

How to protect masonry units in cold weather?

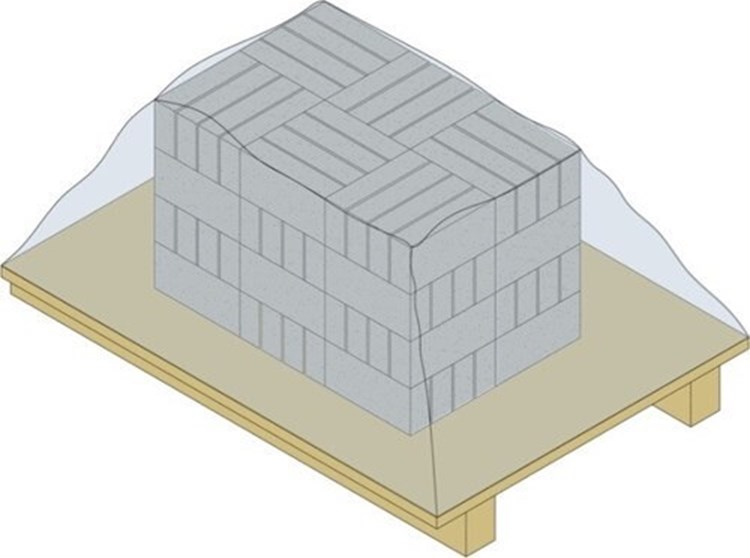

When working in cold weather, it’s important to follow cold weather masonry procedures to protect your product. This includes things like providing covers to protect your materials from frost, snow and ice. This is particularly true of bricks, blocks, sand and cement. Frozen materials should never be used when laying brick or in any circumstances. Always wait for temperatures to rise before laying bricks in cold weather. Cold weather can stop the bond between the mortar and brick setting correctly. This usually occurs at temperatures below 2°C.

Image of covered and thereby protected blockwork

How to protect masonry work in cold weather

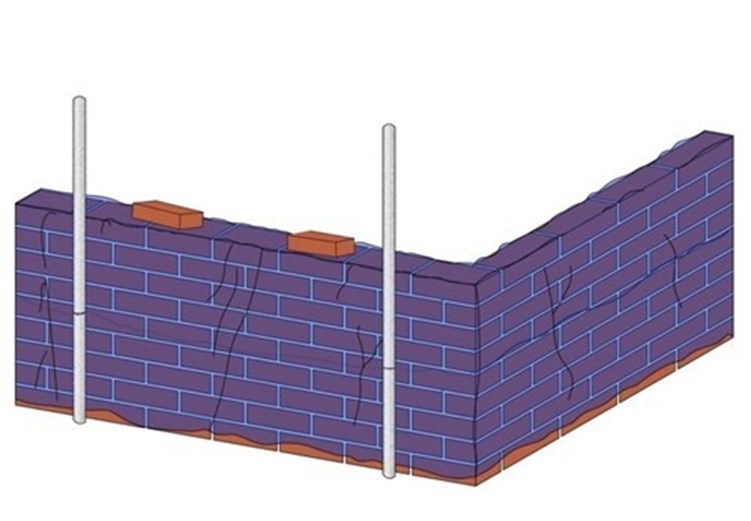

Any newly built walls or other masonry construction will require protection against frost where temperatures are expected to drop below 2°C. You should be protecting all masonry with polythene or hessian, ideally. If temperatures are expected to fall to an extremely low level, anti-freeze agents like insulation boards may be required and heated enclosures may even need to be considered.

Finishes including rendering, plastering and screeds

Rendering should only be finished if the temperature outside is at least 2°C and rising. There should be no frost within the construction that is to be rendered and where possible, rendering should not take place where freezing weather conditions are anticipated prior to adequate curing.

It is important to note that no plastering or screeding should take place unless the building is free from frost. It is acceptable to use internal heating to warm the building, however it is important to make sure that the heaters do not produce excessive vapour within the dwelling. Adequate ventilation should be provided to allow moist air to escape. The structure should be appropriately pre-heated before plastering and continue to be heated as the plaster dries.

Checklist from the Brick Development Association

The Bricks Development Association makes a number of recommendations for protecting newly-laid masonry in colder months:

- Brickwork should be kept clean and protected from rainfall, snow and contamination.

- Avoid mortar smearing or splashing as the work proceeds.

- Staining of brickwork often comes from excessive wetting or saturation of recently built brickwork.

- During breaks in construction, take particular care to keep bricks and brickwork in progress covered with waterproof sheeting.

- If overnight frost is likely before the mortar within newly constructed brickwork has fully set, it should be protected with an insulating layer of hessian underneath the polythene. This would normally give some protection to the mortar joints from overnight frost.

For further information on working in cold weather you can download Appendix C of our Technical Manual.