Warranty stance

Batten spaces often need to be ventilated where this a potential for warm air to condensate and rot the battens out. Our stance is batten spaces should be ventilated for warm or cold pitched roofs where an LR (low resistance) underlay is used in combination with an impermeable roof covering.

Provision of information

- For warranty purposes we require the following:

- Design details showing the ventilation strategy for the pitched roof to be in accordance with our Technical Manual and BS5250 and;

- Third party product conformity certificate for any LR underlays used and;

- Written confirmation and evidence must be sought from the manufacturer confirming the tiles/slates are considered air permeable or air impermeable as stipulated in BS 5250. For example, some fibre cement slates may be considered air impermeable whilst some and traditional double lap plain tiles may be considered air permeable.

Some tile manufacturers will not have this test information, in such cases we would assume the worst case (that the tiles are air impermeable). For further information please see the ‘Other Consideration’ section at the bottom of this article.

Batten space ventilation to cold pitched roofs with LR underlay

Where air impermeable roof coverings are used with an LR underlay to a cold pitched roof proposal there is a risk of moisture accumulation on the underside of the outer weatherproof covering (within the batten space under the tiles).

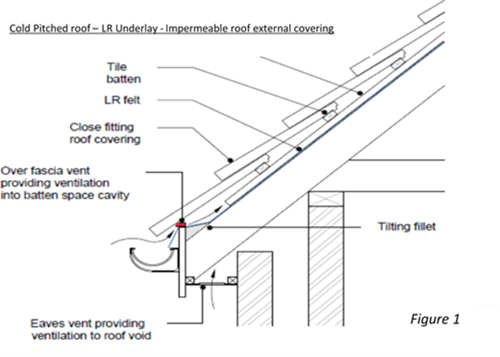

To reduce the risk of potentially damaging condensation, the batten space should be ventilated (see figure 1). This should be achieved by means of counter battens and vents at both low and high level:

- Low-level vents should be equivalent in free area to a slot 25 mm deep running the whole length of the eaves. Over-fascia vents should provide ventilation into the batten space

- High-level vents should be equivalent in area to a slot 5 mm deep running the whole length of the ridge in accordance with BS5250

- Eaves vent should also provide ventilation to the cold roof void as per BS5250

Note: Alternative methods of ventilating the batten void should provide an equivalent level of ventilation.

If the batten space is not ventilated, there needs to be an increased level of ventilation to the roof space and that should be in accordance with BS5250. The underlay manufacturer’s 3rd party accreditation also needs to be followed. It is very difficult to determine a HR or LR underlay by sight alone and the manufacturer’s third party accreditation should be referred to.

Batten space ventilation to warm pitched roofs with LR underlay

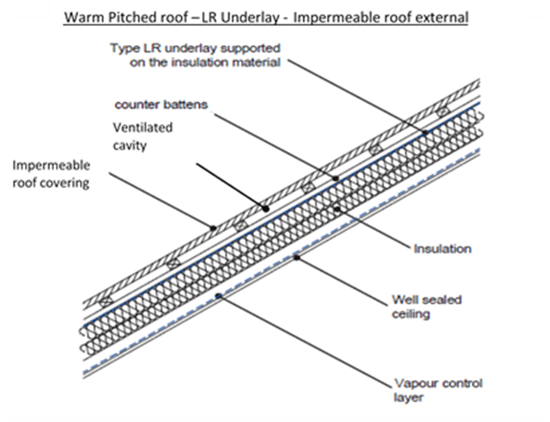

Warm pitched roofs with LR underlay, an Air and Vapour Control Layer (AVCL) should be provided at ceiling line. Where an external covering (such as fibre cement slates) is air impermeable there is also a risk of interstitial condensation forming on the underside of the underlay and the external covering, to avoid that risk the batten space should be ventilated as described above.

Batten space ventilation to cold pitched roofs with HR underlay

A High Resistance (HR) underlay provides high vapour resistance on the cold side of the roof void, preventing the diffusion of water vapour from the loft in to the batten space; it is therefore essential that the loft space be ventilated in accordance with BS5250 and the Roofs section of our Technical Manual.

Batten space ventilation to warm pitched roofs (Insulation along the rafter pitch) with HR underlay

In warm roofs (with insulation along the rafter pitch) with an HR underlay, whatever form of external covering or ceiling is provided, there is a risk of interstitial condensation forming on the underside of the HR underlay; to avoid that risk, an AVCL should be provided on the warm side of the insulation, and ventilated voids should be formed between the underside of the underlay and the insulation.

Other considerations

Determining if the underlay is HR or LR

It is very difficult to determine a HR or LR underlay by sight alone and the manufacturer’s third party accreditation should be referred too.

Determining if the roof covering is air impermeable

As can be seen throughout this article, an important factor when determining if the batten space needs ventilation is if the roof covering you’ve chosen is air impermeable For discontinuous roof coverings (tiles, slates etc.) written confirmation and evidence must be sought from the manufacturer confirming the tiles/slates are considered air permeable or air impermeable as stipulated in BS 5250:

‘The air permeability of an outer weatherproof covering comprising discontinuous units may be determined by testing in accordance with BS 5534:2014+A2:2018, Annex L, using equipment capable of measuring pressure differences of 10 Pa.’

Some tile manufacturers will not have this test information, in such cases we would assume worst case (that the tiles are air impermeable).

Batten space ventilation for decorative cladding

This article has dealt with batten space ventilation for pitched roofs, however there should be consideration for providing a drained and vented cavity for decorative cladding on the external face of a masonry substrate. One way of achieving this is with the use of counter battens and a fly mesh at low and high level (to prevent insects getting inside the batten space).

Warranty position

The determining factors for batten space ventilation is if an LR underlay is chosen in combination with an impermeable roof covering. In these situations, batten space ventilation as per the above should be provided. Any deviation from the above should be in line with BS5250 and prior agreement must be sought from your warranty surveyor.