When are lateral restraint straps required?

At floor and roof constructions, walls require lateral restraint by tension straps in accordance with the provisions in BS EN 1996-2:2006 and Building Regulation requirements.

Lateral restraint straps are required at floor and rafter or flat roof member levels. If you are building a pitched roof you will also need to use straps at ceiling joist levels. Provision is necessary, should the height of the wall exceed recommended values found in BS EN 1995-1-1:2004 and current Building Regulations.

Best practice of lateral restraint straps

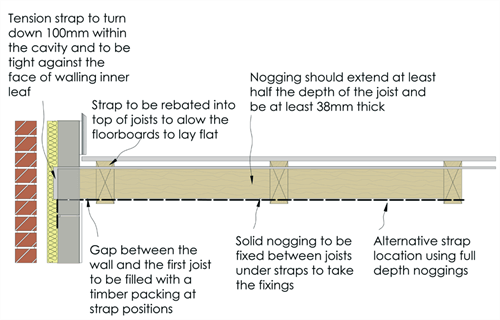

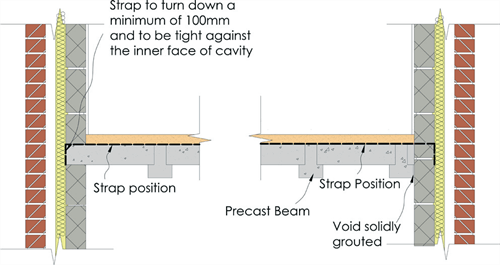

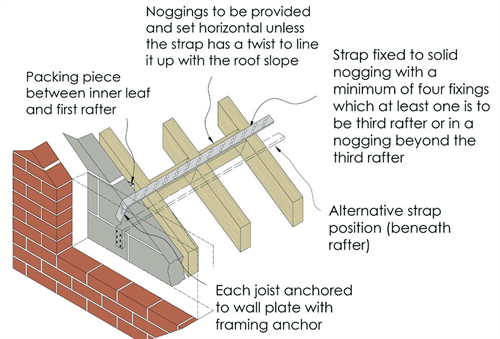

- Ensure all restraint straps fit tightly against the masonry face within the cavity.

- Use blocking in the gap between the joist / rafter and the parallel wall at all lateral restraint strap positions as well as in between joist / rafters for the length of strap required.

- Lateral restraint straps at floor or roof level must not be retro fitted by plug and screwing the strap to the masonry.

- Restraint straps must turn down the cavity by at least 100mm and be tight against the face of the wall.

Timber floor / wall detail

Suspended concrete beam and block floor / wall detail

Rafter / gable wall detail

For more information please refer to our Technical Manual and check out our blog on how to use lateral restraints during construction.